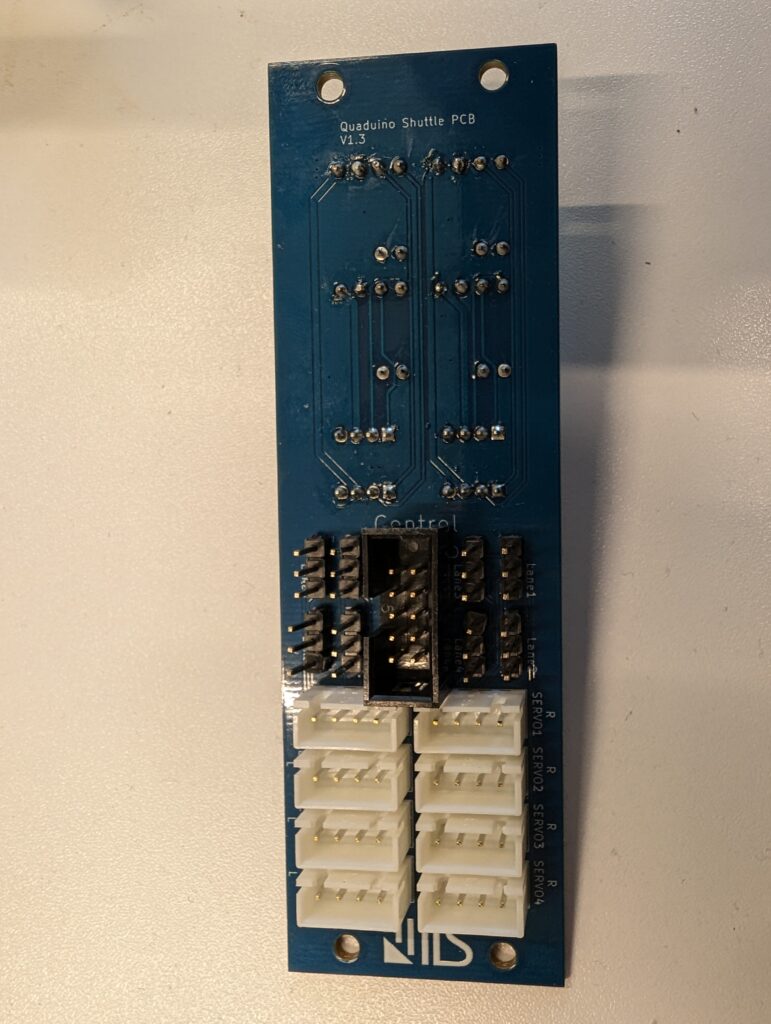

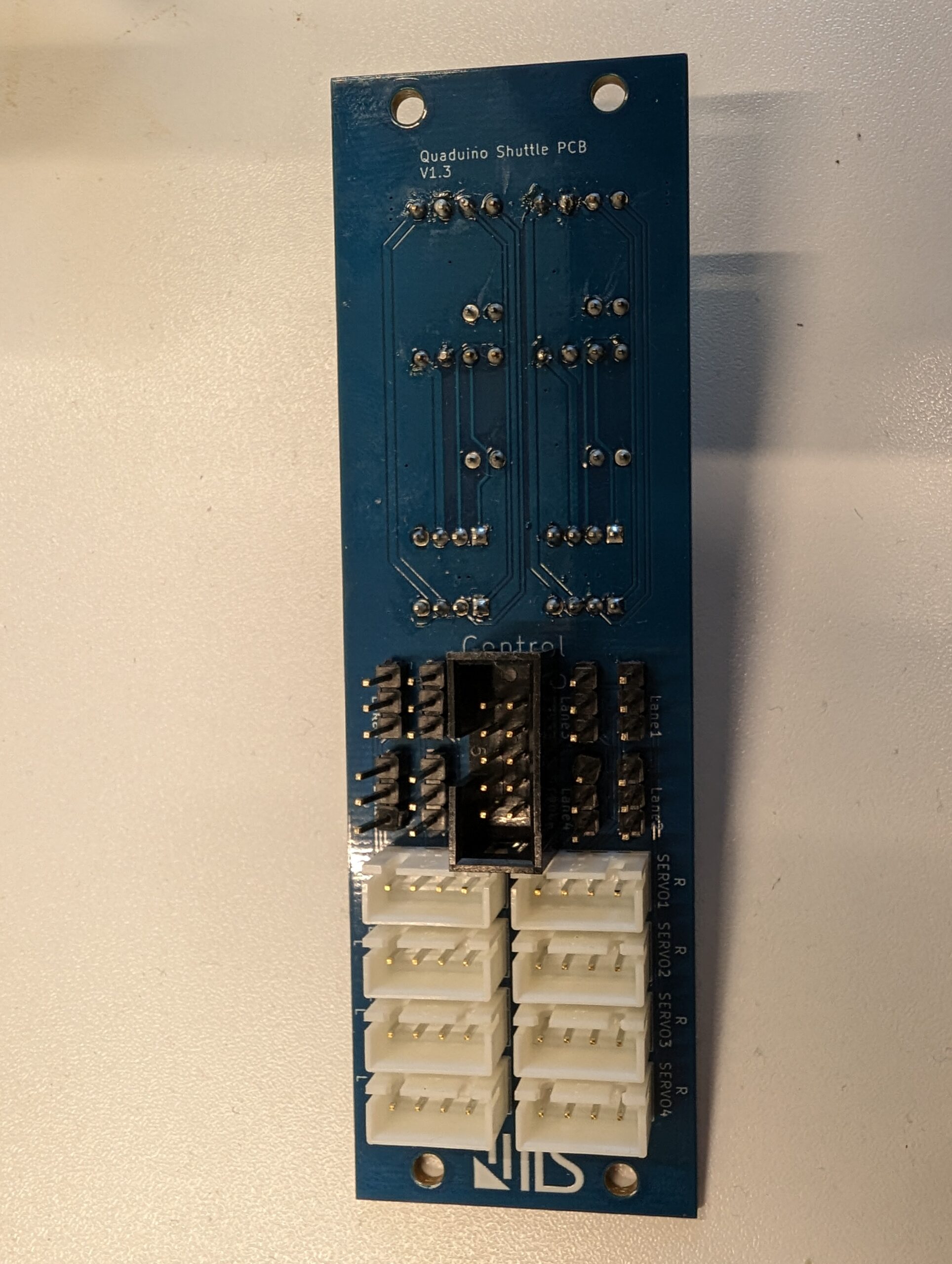

After redesigning the shuttle airframe, the next bottleneck was wiring and maintainability. Our answer: a custom Shuttle PCB that brings power, sensors, and actuators into the shuttle model.

Why We Built Our Own Board

- Reduce cabling complexity and assembly time

- Provide stable, well-documented power rails and protections

- Standardize connectors for sensors, servos, and peripherals

- Improve reliability under demo and classroom conditions

What’s on the Board

- Connectors for each Quaduino lane to the shuttle

- Connectors for 4 time-of-flight (ToF) distance sensors — one sensor per lane

- Connectors for 8 servos to move the elevons — two servos per lane

- Connector for servo-position feedback to the control Arduino (environment simulation)

Reliability in the Real World

We built for the realities of outreach and events:

- Quick swap: modular mounting and connectors enable 5–10 minute board/sensor/servo swaps.

- Label-first design: port labels and physical layout match the hardware connectors.

What This Enables

- Faster setup for Mini-Shuttle kits

- Demonstrations in System Design I

- Sensor and Actuator Lab Course for System Design II

Lessons Learned

- The first PCB never works correctly.

- Too many cables make everything hard.

- Custom PCBs make it a bit easier and more consistent.

Schreibe einen Kommentar